Project Phoenix is the Rocket Team's first mid-altitude two-stage team rocket. It was preceded by staging demonstrator 2, the progenitor of its passive drag-separation design. Phoenix has a few upgrades from these rockets, notably more robust fins, made in house of 0.25" aluminum. The rocket also has different aeroshell designs than those pictures above (aeroshells are the diamond-shaped mounts that hold cameras), but this wasn't shown in this version of my render. The Phoenix nose cone has also been replaced with a larger, black nose cone in order to account for a larger parachute for our test launch, where we changed the motor internals so the rocket would go to a lower altitude.

Phoenix has a 40" long N-class motor burning Angry Goat, an ammonium perchlorate composite propellant with a magnesium additive to decrease slag formation and increase burn rate. The second stage flies a 31" M-class motor with the same propellant. I don't have an ITAR certification or chemistry knowledge to design propellants, but hope to learn more in the future from our team's new chief engineer and propulsion leads.

The first stage is set to fly to 16,500 feet, with the head-end ignition then firing up the sustainer motor to then fly to 52-60,000 feet.

Me machining the mission package tube in the Edgerton machine shop

The booster avionics tower

When I arrived as a freshman, I worked finalizing the design for Phoenix. Although the design was mostly finished, I was able to refine some of the internals before we moved to manufacturing. Most notably, I conducted some FEA work in order to more refine the load-bearing capacity of the mission package tube forward bulkhead, which would take the bulk of the force from the avionics components in flight. The rear bulkhead, which you can also see above, was thickened in order to accommodate a higher load and was given a direct mounting mechanism to the rocket. There were also modifications in the bulkhead designs for the sustainer (our upper part of the rocket) to allow for bulkier electronics. Going from a triangular design (as soon below, very similar to the booster) to two panels.

The old, triangular mission package design

The new design with all components and aluminum forward bulkhead

I worked to make sure the new aluminum bulkhead was properly mounted, mass-optimized, and able to withstand the forces of the new design. I also simulated the loads the two would experience to confirm the change in design would be feasible.

I started my major involvement on the team after being selected as the structural lead. Over the transition period of summer 2021, I did lots of work developing a teaching program to onboard new members to the subteam. Although CAD was not a large focus in the fall semester, a lot of machining and calculation skills were taught for onboarding.

As structures lead, I led the manufacture of most components for project Phoenix. This included most of the body tubes, avionics bulkheads, avionics panels, forward retention rings, and piston mounts. I used a lot of these parts to teach newer members how to use heavy machinery like the mill, lathe, waterjet, and a plethora of hand tools.

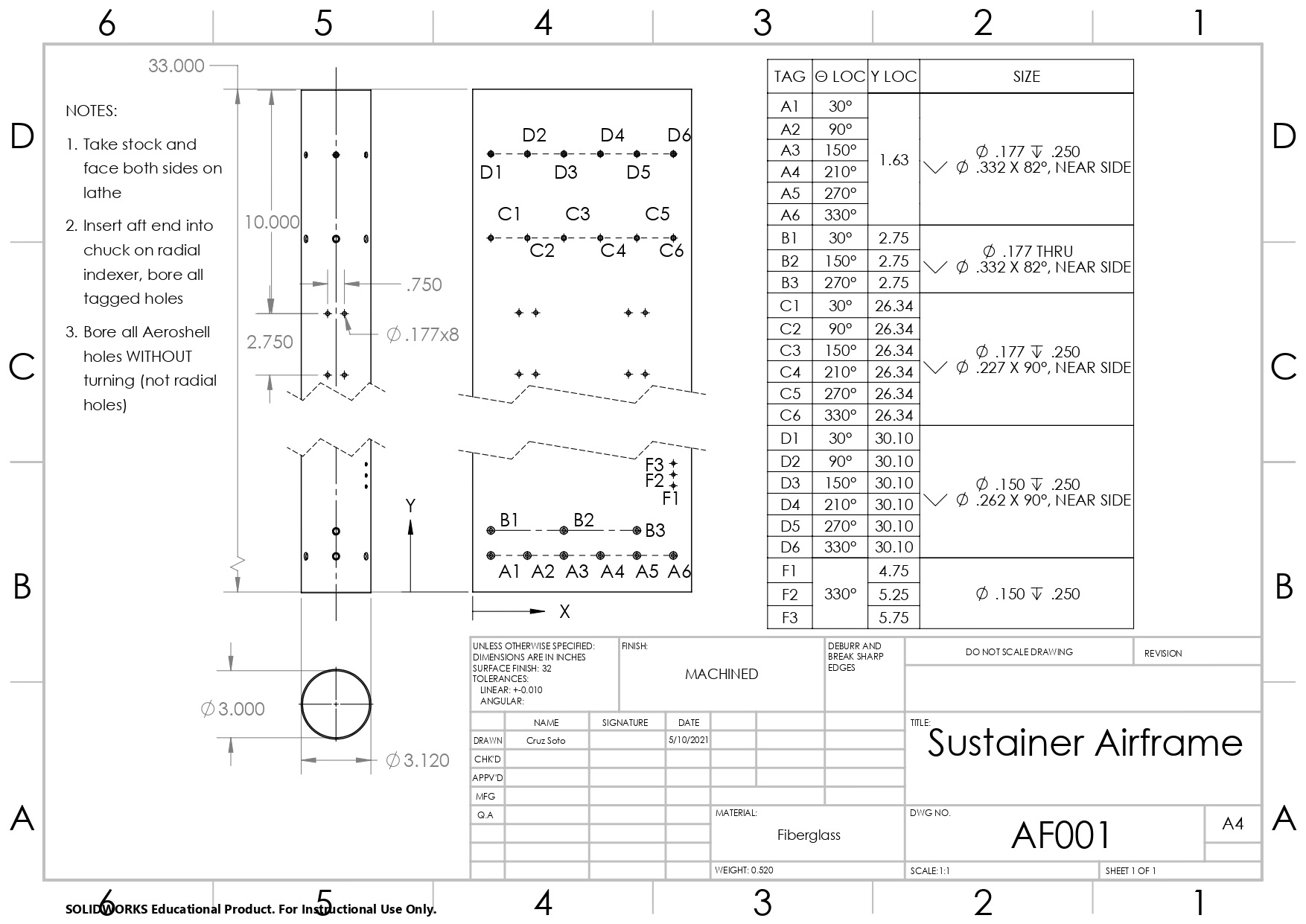

The sustainer mission package tube

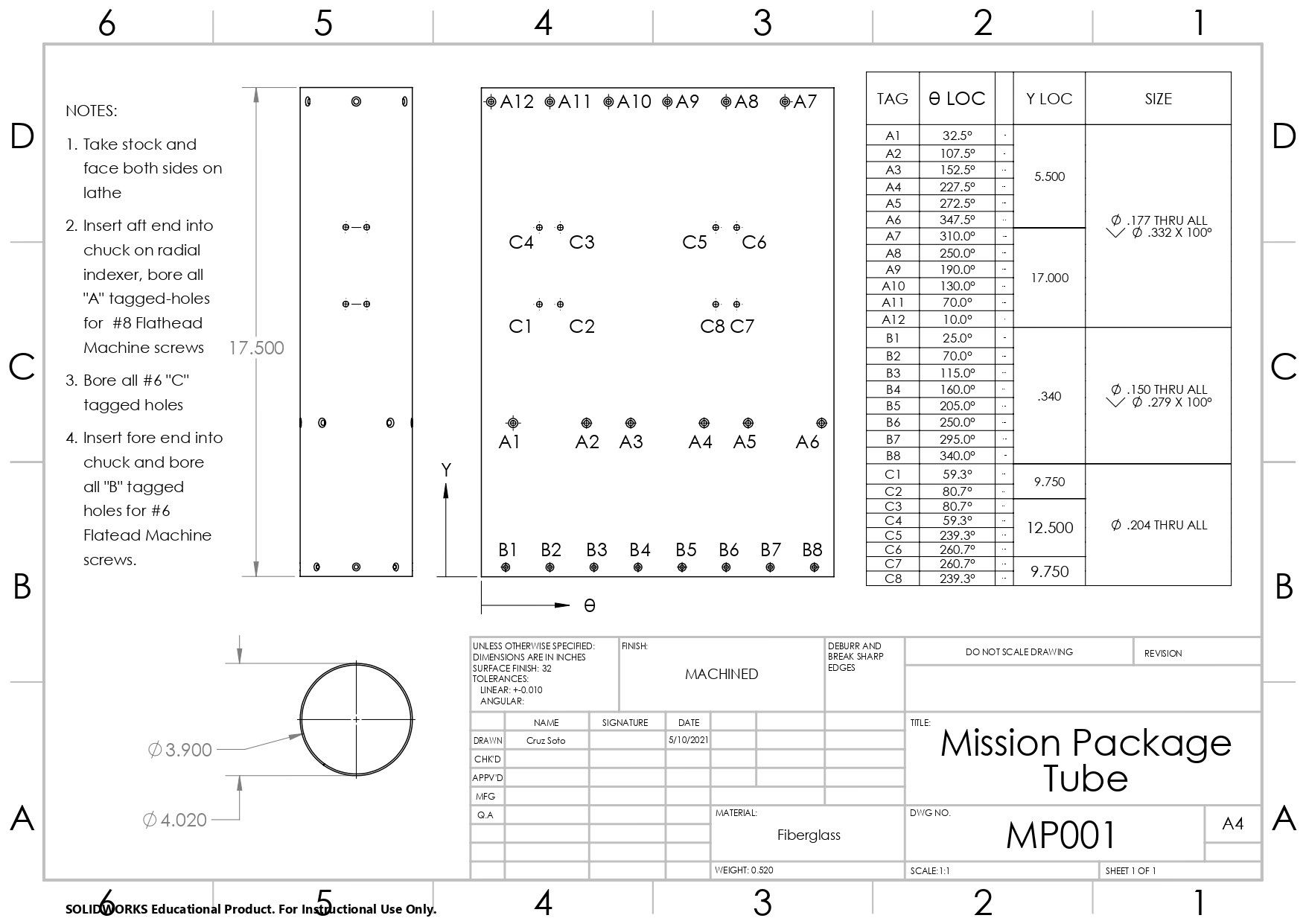

The booster mission package tube

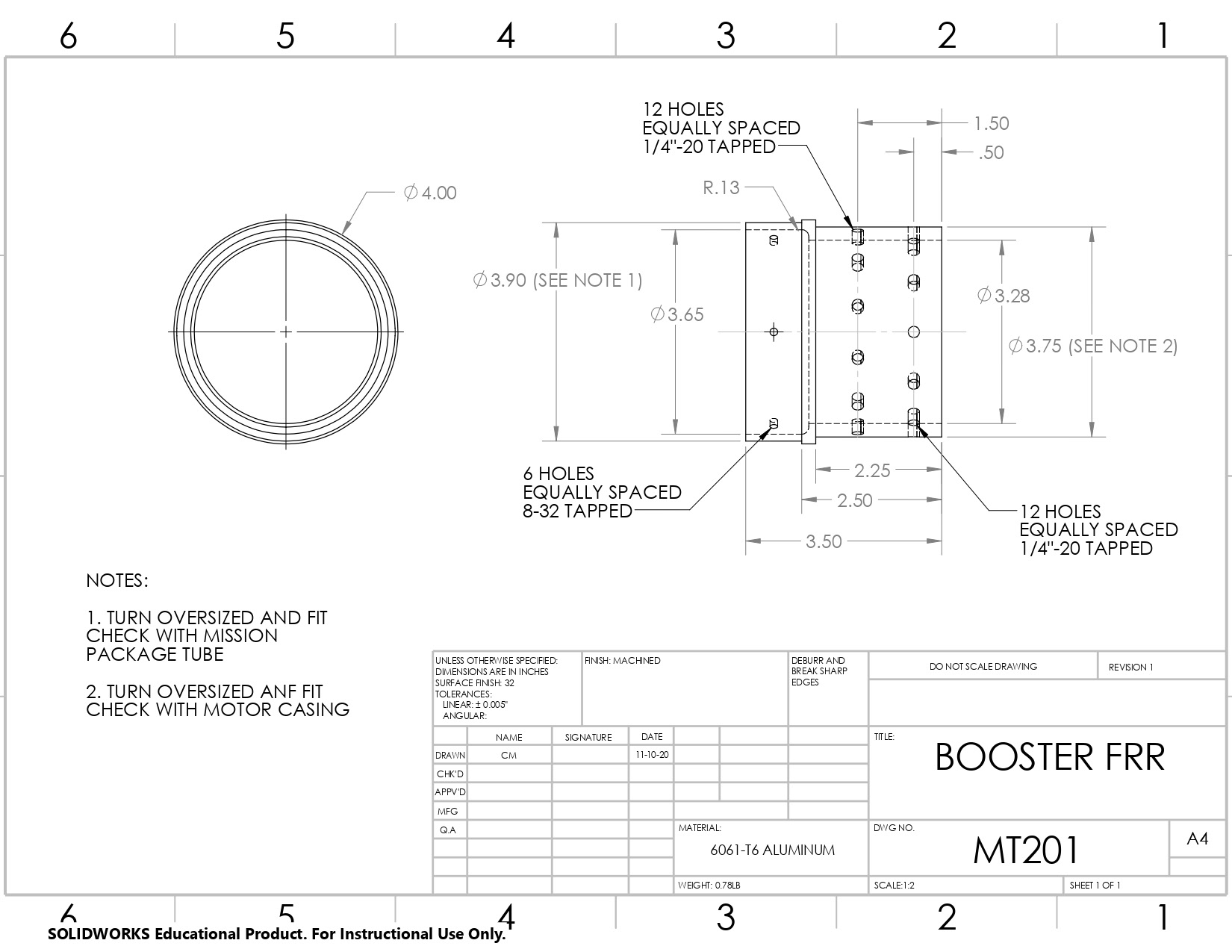

The booster forward retention ring

*Note that all of these are older designs and have since been updated, so are impractical for flight. They are shareable under ITAR as they do not contain any information about motor design.*

After lots of manufacturing, I worked alongside the Recovery team to begin integrating the rocket. A video of which is shown in the presidential section of the site.